TRITON DRILLS

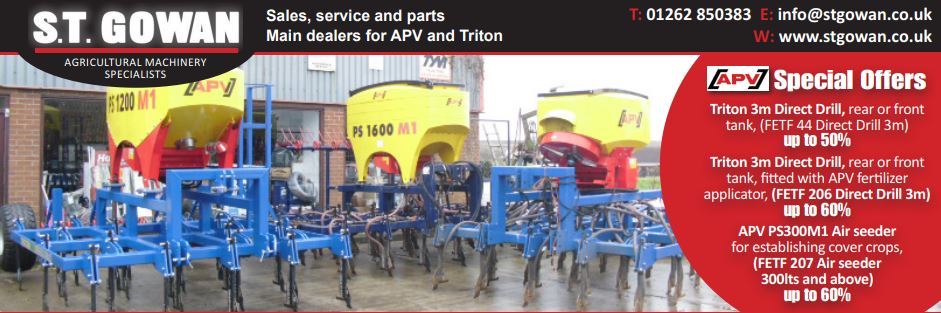

NEW GRANTS AVAILABLE Contact us for more information

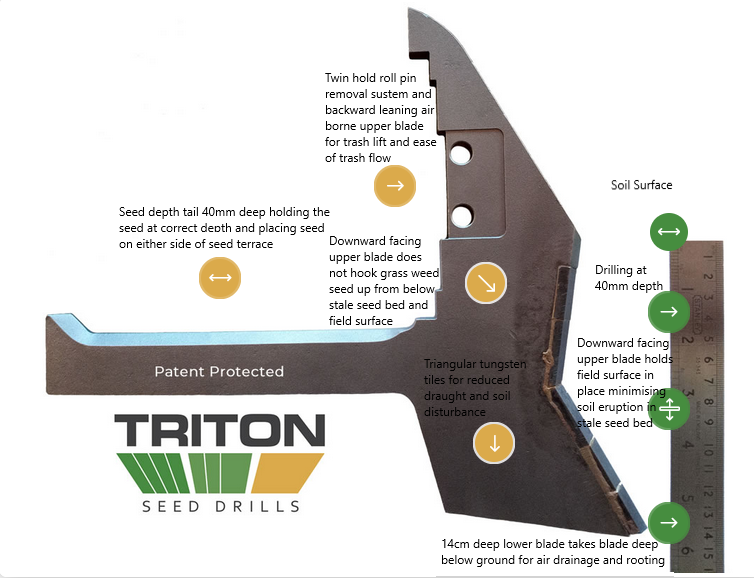

The Triton Blade Design

for reduction of grass weeds in the seeded row

Have you sometimes found grass weeds in the seeded row but the rest of the stale seed bed has stayed clean? Maybe the weed seed came in the wheat seed ? Nope..

The patented Triton drilling blade is unique in having a downward facing stale seedbed engagement member. All other tine drills use upward facing soil engagement members which hook weed seed upwards into the top two inchs of the seed bed i.e the germination zone. This defeats the stale seed bed system giving enough grass seed return to cause difficulty in the rotation.

A shallow stale seed bed, or multiple stale seed beds in an infested field, can reduce weed burden by 95% if the crop is then drilled in late autumn. But the vital last pass, the drill pass, can defeat the successful stale seed bed by hooking up the grass seed, the Triton cannot hook up weed seed, this is a very significant advantage.

[please note positioning of the icons on the illlustration are approximate and for display purposes only]

BRAND NEW 5.15M FOLDING TRITON DRILL WITH A GUTLER ROLLER PRICE: POA GIVE US A CALL ON 01262 850383 FOR MORE INFORMATION

If you would like any information to this drill please contact us either by our contact page or giving us a call on 01262 850383

Below please take a look at a few photos before the demonstration, Further down the page you will aslo see our current stock of Triton Drills + some of our Ex Demo Machines

REQUEST A CALL BACK ABOUT OUR TRITON DRILLS

Key Features about a Triton Drill

Can be used as a low distrubance cultivator for effective non-burial weed seed chitting and as an inter-row hoe

It has no rear press or roller wheels that would stop the drill working in sticky soils

Side Press tines give horizontal consolidation of the seed bed; Creates a secure platform at correct depth for any seed

Multi-width drill - Triton Seed-Press Seed Drill can quickly be reduced in size to aid traction

Six inch seed row spacing for maximum yield

Every seed row has depth rooting trench

All plants given deep-rooting potential and full radius root ball to maximise nutrient and moisture take up#

Heavy duty frame for fully controlled drilling operations in ay soil conditions, without compromise

Ability to direct drill into wet clay in mid-winter securing seed from sluga without rolling

Oilseed rape 'four and two' drilling for max yield and low draft

Tramline leg lift for drilling up exisiting tramlines without ripping them up

Damp conditions depth control sledge facility

Basal fertiliser placement option on rear-closing press tines

Trash clearance - 770mm bespoke tines

Impact Protection pads for legs

Hard wearing Boron steel and tungsten carbide drilling blade

Reversible boron steel drilling blades via two bolts

Weldable boron carbide replacement tiles supplied to reduce the wearing metal bill and prolong the life of the reversible blades

No matienance is required on the drill apart from turning the wearing points occasionally

Front mounted seed hopper keeps the weight over drilling blades constant in order to provide consistent seed depth. Also, radar seed metering and on the move seed rate adjustment

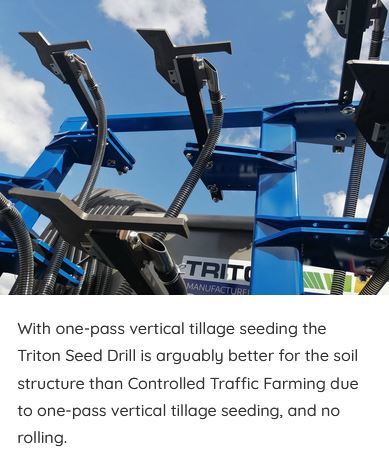

The Triton side press seed drill removes the only downward pressure in Controlled Traffic Farming by removing the need for rolling

CURRENT TRITON DRILLS STOCK LIST To make an enquiry today about a Triton Drill please contact us on 01262 850383 or fill out our contact form and we'll get back to you Trition Drills are available in 3m, 3.6m, 4m, 4.8m, 6m, 6m Folding, 8m Folding

TRITON 6M FOLDING DRILL

Hydraulic Folding

Rear Lights & Marker boards

Options:

Rear seed tank

Front tank

Pre Merge Markers

Tramliner

Rear access platform

Rear Harrow

Price: £54,900 (Drill Only)

TRITON FRONT & REAR TANKS

1500L Capacity

Accord Metering System

RDS Artemis Control

Front Tank: £15,400

Rear Tank: £15,150

TRITON 5M FOLDING SEED DRILL (EX DEMO)

Triton 5m Folding seed drill, ex demonstration. 30 seeding blades. 15 closing blades. Tramliner kit fitted full width rear following harrow. Rear Lights. Wheel scrapers.

Price: £39,000 (Drill only)

TRITON 3M DRILL

Rear Seed Tank

Accord Metering System

RDS Artemis Control System

Access Platform

Rear Following Harrow

Rear Wheels

Lights & Marker Boards

Price: £40,450

TRITON 3M SEED DRILL

Triton SP300M seed drill,(2.9m) drills at 3m using the outer cranked tines ,seed distribution head ,rear adjustable depth wheels, rear press rake.

Option:

APV Rear Seeder for applying Avadex granules, Micro Granular Fertiliser, Small Seeds

Price: £25,300

Browse through our current stock of high quality approved used agricultural machinery, vehicles and equipment, including:

Tractors

Balers

Combines

Cultivators

Trailers

Combines

Sprayers

Harrows

Drills

Ploughs

Spreaders

Hedge-cutters

All pieces of equipment we sell are available at competitive prices, and have been thoroughly tested by our experienced team of specialists to ensure that they are in full working order and ready to use.

We’re always getting new stock in, so if you can’t find what you’re looking for here, or are searching for a specific piece of equipment, please get in touch. We have extensive industry contacts and are able to source machinery, equipment and spare parts for customers if required.

CONTACT US FOR OTHER SERVICES AND MACHINERY

In addition to used agricultural machinery, we also offer spare parts, repairs and servicing for a wide range of equipment.

For additional information about any of the machinery we have in stock, please get in touch today by calling 01262 850 383 or by emailing info@stgowan.co.uk

PRICE LIST

ALL PRICES ARE EXCLUDING A SEEDER

3M RIGID TRITON DRILL: £25,300

3.6M RIGID TRITON DRILL: £26,400

4M RIGID TRITON DRILL: £27,500

4M FOLDING TRITON DRILL: £45,100

4.8M FOLDING TRITON DRILL: £48,400

6M FOLDING: £54,900

TRITON FRONT SEED TANK: £15,400

TRITON REAR SEED TANK: £15,150

MACHINES ARE EX WORKS AND DELIVERY IS AN ADDITIONAL COST

OPTIONS:

Pre Emergence Marker Kits: £1950 + VAT

Bout Markers: £2250 + VAT

Tramlines Kit: £600 + VAT

CONTACT US TODAY:

01262 850383

OR

FILL OUR AN ENQUIRY FORM AND WE'LL GET BACK TO YOU

TRITON EX DEMO/EX PROMO MACHINES

TRITON 5M FOLDING SEED DRILL (EX DEMO)

Triton 5m Folding seed drill,

ex demonstration.

30 seeding blades.

15 closing blades.

Tramliner kit fitted full width rear following harrow.

Rear Lights.

Wheel scrapers.

Price: £39,000 (Drill Only)

TRITON 3M EX PROMO DRILL

From one of our recent promotional machines using a APV PS1200 M1 Seeder

18 Seeding Tines

9 Closing Blades

Rear Press Rake

Depth Wheels

Very little use

Price: 29,950 (Including APV Seeder)

SECOND HAND TRITON MACHINERY

Triton 4m drill fitted with the APV PS1600M1 Seeder

Triton 4m drill fitted with the APV PS1600M1 Seeder unit,24 seeding tines with 12 closing tines,rear depth wheels

Price: £27,500 (Price with Seeder)

TRITON 4.8m drill fitted with the APV PS1600M1 seeder

Triton 4.8m drill fitted with an APV PS1600M1 seeder unit,rear press rake,30 seeding legs and 15 closing tines.

Price: £35,500 (price with seeder)

Clay soil in Lincolnshire

Standing water on clay soil in Grantham, Lincolnshire, 17 October 2017, after being direct drilled by a Triton Side-Press Seed Drill 4m. The second image is of the same spot on the same field 10 days later with a healthy wheat crop growing.

Skyfall 5th wheat direct drilled Nov 2020

6th wheat drilled Nov 5th photo May 11th 2019

Gravity wheat direct drilled by Triton Nov 1st , 3x 1.5litre AminoA Flo applied taken May 4th 2019 in prolonged drought

Click on this text to edit it.

Lets take a closer look at our drills.....

TRITON 3M DRILL

A close up look at the drill once all been piped up to the APV PS800 Seeder.

Any questions feel free to get in touch with us on 01262 850383 or enquire today.

TRITON DRILL DELIVERY

Our most recent delivery ready to go out to customers. All checked and ready to go.

Any questions feel free to get in touch with us on 01262 850383 or enquire today.

TRITON DRILLS FAQ'S

At what speed can the Triton work?

It is recommended to pull the Triton at a speed of between 8kmh and 18kmh. However, ensure your soil type and conditions allow the seed to be held at the right depth for the speed you are travelling. The faster the tines go through the soil the more the trash falls off the legs as they vibrate on the rubber impact pad system.

Why was a new rubber impact protection and vibration system introduced instead of using the existing beam clamps with four rubber rods?

While they are satisfactory on light disc harrow mountings or in light duty tine drills*, the beam clamps that pinch four rubber rods are simply not strong enough. The Triton is far too precise to have any movement or malfunction risk. The new rubber impact pad also allows the Drill to utilise individual tine lift features.

* Although, even in light duty, theses clamps move on the beams.

Which parts are patent applied?

Patents cover:

the seeding blade design;

the blade to leg design;

the small seeds and soil interuptor;

the seed-splitting tile;

the two side-press features;

the vibrating rubber impact pads.

Do Triton parts fit any other manufacturers legs and brackets?

As far as we are aware, Triton parts only fit with other Triton parts.

Are drill components sold separately by Triton or in kit form?

Triton only sells seed drills as fully operational units.

Can I make my own side-press drill if I don’t look to sell it?

It is a patent infringement for crops to be sold or fed or used for any commercial purposes if unlicensed patented parts and systems have been used in the crop production.

How long do the Tungsten pointed seeding blades last?

We estimate 2000 acres of use in medium loam/ clay soils on a 4m Triton Side-Press Seed Drill. However, this is an estimate because we have yet to wear any out yet. It takes about one minute to change a seeding blade.

Why is the Triton Side-Press Seed Drill maintenance free?

Apart from two sealed bearings on the depth wheels, the Triton has no moving parts. As a result, there is no wear and no greasing required. No replacement drill or expensive refurbishment will be needed, and the Triton will offer many years of hard work.

Are there any other advantages to a front-mounted tank?

Having the tank on the front allows the Triton Side-Press Seed Drill to be carried with the depth wheels raised off the soil in extreme wet clay conditions. Tractors can hold the evenly weighted Triton at effective seeding depth with no depth wheels. The Triton Side-Press and seeder blades are self-cleaning when in work so, by lifting up the depth wheels, drilling can continue in virtually all conditions.

Is there a plan for Triton to produce a rear seed hopper version?

There are no plans for a rear hopper. The Triton Side-Press is incredibly versatile, with every seeding leg individually alterable for depth and vibration. This allows tramline legs to be lifted and legs lifted for rape and bean drilling row combinations. The front tanks are inherently helpful to seeding operations. The weight is on the front tyres for increased grip and the seed coulters have constant weight over them so the depth does not alter in soft winter conditions as the seed tank empties. All of the drill can be seen and adjusted from above.

Do the seeding blades need to be changed for beans and rape?

No, nothing needs changing between crops. From grass seed and rape, cereals to maize, the drill is perfectly set up at all times. Only depth adjustment is needed, which takes approximately a minute’s preparation.